Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

LPG Storage Tank Operation Manual

Warning

Before using the LPG storage tank, the safety accessories must be assembled with the tank for air tightness test and do the nitrogen replacement for the tank with a pass result.

Contents

1. Summary---------...................--....-----......----------4

2. Technical Feature -----------------......--------------4

2.1 Design Standard - ---------..--....----------.--------4

2.2 Technical Feature (Table 1)-------------..---....---------4

3. Construction ---------------.-------.---....------.--5

3.1 Sketch ------------------------.-...---.----------5

3.2 Nozzle Table(Table 2) -------------------......--.------5

4. Safety Accessories Adjustment and Equipment Installation --.....-.-.--5

5. Key Point for Equipment Safety Usage--------------...-...-.-.--6

6. Operation management and maintenance -------------.-....-.-.--7

7. Periodic Checking ------------------------...-..-.--8

8. Supplement: Comparison Table for Liquid Level, Volume and Weight---.-9

1. Summary

The horizontal tank is the special equipment used for storage of liquefied petroleum gas (LPG) when the saturated vapor pressure is less than 1.77 Mpa at the temperature 50℃ and the safe storage is 19.95 tons. The LPG storage tank is designed according to the TSG R0004-2009 "Stationary Pressure Vessels Safety and Technical Supervision Regulation" and requirements of GB 150 [Pressure Vessel". Manufacturers should have the A2 level manufacturing license issued by the state administration of quality supervision, inspection and quarantine administration of boiler and pressure vessel. At any time, the factory should accept the inspection and supervision by the boiler pressure vessel examination board in local technical supervision bureau in the process of design, fabrication, inspection, delivery and any other production step and get the inspection reports issued by them. The inspection report with the built drawings, product quality certificate, certificate of quality, brand extension and design calculation and other technical information issued by manufacturers should be given to users. Users with the above data go to register in the local boiler pressure vessel inspection agencies. Products can be put into use after getting the registration number.

2. Technical Feature

2.1 Design Standard

1) "Pressure Vessel Safety Technology and Supervision Code"

2) "Pressure Vessel" (GB150)

3) "Steel Horizontal Vessel"(JB/T4731)

Other related rules, regulations and standards, etc

2.2 Technical Feature

Table 1

| No. | Name | Value | Unit | No. | Name | Value | Unit |

| 1 | Filling Medium | Liquefied Petroleum Gas (Propane) | 7 | Maximum Working Temperature | <50 | ℃ | |

| 2 | Vessel Category | Ⅲ | 8 | Volume | 50 | m3 | |

| 3 | Tank Material | Q345R | 9 | Filling Capacity | 19950 | Kg | |

| 4 | Design Pressure | 1.77 | Mpa | 10 | Maximum Filling Height(20℃) | 2050 | mm |

| 5 | Design Temperature | 50 | ℃ | 11 | Overall Dimension (LxWxH) | 9212×2728 ×3318 | mm |

| 6 | Maximum Working Pressure | 1.77 | Mpa | 12 | Tank Weight(Naked) | 10650 | Kg |

3. Construction

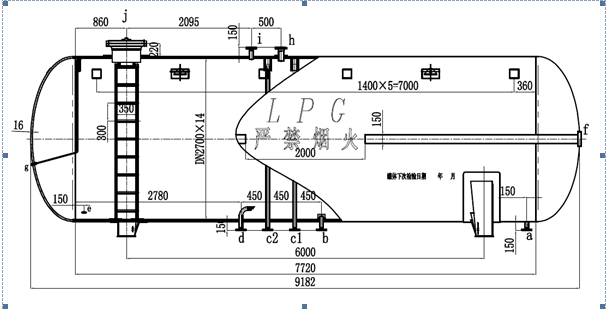

3.1 Sketch

3.2 Outlet Table (Table 2)

Table 2

| Code | Nominal Size(mm) | Connective Forms | Name |

| a | 50 | RF | Drain Hole |

| d | 50 | RF | Liquid Outlet |

| C1-2 | 50 | RF | Gas Regulation |

| b | 50 | RF | Liquid Inlet |

| e | M20X1.5 | Whorl | Pipe for Thermometer |

| g | M33X2 | Whorl | Pipe for Pressure Gauge |

| f |

|

| Float level meter |

| h | 80 | RF | Safety Valve |

| j | 450 | FM | Man Hole |

| i | 50 | RF | Empty Hole |

4. Safety Accessories Adjustment and LPG storage tank Installation

4.1 Users must equip tanks with safety accessories matching the technical parameters according to the standard. Safety accessories must conduct re-inspection before equipping on the tank. Adjusting must follow provisions of the general layout design. Safety accessories installation organization must have related qualified certificate .

In tanker installation, base surface of tanker should be not less than 1 m above the ground. base surface should install base plate. Base installation for embedded anchor bolts is as below.

|

To keep the tank move freely in axial direction, double nuts are used for locking as above. After the lower nut was totally tighten firstly, then loose the nuts by one thread, in this way the base plate can slightly slide in axial direction. In bolts installation, make sure each bolts have at least 10mm space to allow the nuts installation. The stationary saddle should be directly tightened by nuts. Grounding line on the saddle should be well grounding.

5. Key Point for Equipment Safety Usage

5.1 Before LPG filling, LPG storage tank must be conducted nitrogen replacement to ensure safety. The oxygen content in the tanker must be lower than 3℅.

5.2 Safety valves should be tightly closed under normal working conditions. The Safety valve opens automatically when the tank overloads, environment temperature rises sharply, fire occurs or any other reasons, which makes the tank pressure exceeds the relief valve sealing pressure. When the safety valve relief pressure, the relieved liquid or gas should be recycled or discharged into the air through the safety valve outlet pipe.

5.3 A cut-off valve should be installed between safety valve and the LPG storage tank, to prevent safety valve failure which means it can not be closed and leads to large leakages. Then close the cut-off valve and replace the safety valve. The cut-off valve is fully open during normal working and closed only when replacing the safety valve.

5.4 The seal of the safety valve device shall not be arbitrarily opened, if needs to re-debug, it must be adjusted by the approval organization by the national technology supervision agency.

5.5 On pressure gauge dial, a red line should be printed at design pressure value. An cut-off valve should be installed between pressure gauge and tanker. Under normal working conditions of LPG storage tank, the valve should be fully open, when replacement or testing pressure gauge, the cut-off valve needs to be closed.

5.6 On Magnetic level gauge dial, a red line should be printed at the maximum filling height. When installation, the tanker is completely empty, so the level gauge should be in the zero position. A cut-off valve should be installed between the level gauge and tanker, which is fully open during normal working, only closed the cut-off valve in replacement of the magnetic level gauge.

5.7 On temperature gauge dial, a red line should be printed at the design temperature 50 ℃. Between 40 ℃ and 50 ℃, it should be coated in yellow color.

5.8 The lowest pressure in the LPG storage tank in the process of using shall not be less than 0.05 MPa, which is to prevent the air flow into the tank.

6. Operation Management and Maintenance

6.1 Users of the LPG storage tank must follow the rules of the "Pressure Vessels Safety and Technical Supervision Regulation" and other relevant laws and regulations strictly for safety technology management and prohibit overloading, over temperature and overpressure to ensure the security usage of the tank.

6.2 Technical director of users is responsible for the pressure vessels safety and technical management, and specify the professional technical personnel for the daily technical management of the pressure vessel.

6.3 Tank operators should be tested and approved by the safe education training and get and related certificates.

6.4 Cooling measures must be taken when any of the following circumstance occurs.

A. The pressure gauge indicating the value gets close to the red line, or the pressure is keep increasing.

B. The temperature gauge indicate the value reaches the yellow warning signs.

6.5 When the tank pressure meet the design pressure value (the red line indicates value) and the safety valve does not open, the operator should take immediate measures to reduce the pressure of the tank first, then close the cut-off valve under the safety valve for maintenance, calibration, and rapid installation of the safety valve to let the LPG storage tank back to normal working condition.

7. Periodic Checking

The storage tank should be tested regularly in accordance with the related rules in [Pressure Vessel Safety Technology and Supervision Code".

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.